History - by Lloyd/Griselda's grandchildren

We believe the Wellington woollen business can be traced back to the reign of Queen Elizabeth I, to John Were of Pinksmoor Mill. In 1772 the young Thomas Fox became a partner in his grandfather Thomas Were’s serge (cloth) making company at Trade Court, South Street, Wellington. Thomas went abroad to study languages and the woollen trade, and on his return the company was transformed from a small cottage industry into one of the most successful family-owned cloth manufacturers run by the Fox family for the next seven generations.

In 1796 Thomas Fox, with vision and sound judgement, relocated the business to larger premises, a former flour mill at Tonedale, close to the vital water supply from the river Tone. Fox Brothers as the company then became, operated as a twin vertical company, taking the wool from the sheep and spinning woollen and worsted yarns to weave into cloth. Originally horse-powered, the mill became water and steam powered, before gas then electricity were later introduced.

Thomas Fox with his wife Sarah Smith, set to work to build up their business based on their Quaker values, alongside their family. Sarah, whose own family were London bankers, was in charge of the farm and the counting house, with its characteristic smell of fleece, as well as bearing sixteen children of whom eight survived.

Wool costs were always important and in the 1780s wool smuggling was a great concern. Local supplies of wool were supplemented with imported wool from Ireland, landing at Minehead, with the bales of finished cloth exported from the port at Topsham, and the grandfather clock in the counting house having a special dial to show the tide times. This route was used for imports of fine merino wool from Spain, and subsequently Australia and New Zealand.

Orders of Long Ells, using Cotswold wool to weave a fine white serge, were woven for The East India Company, dispatched in special lion covered wrappers to deter potential looters en route. The orders with China, started in 1785, were vital to the business.

The original spinning Jennies were replaced with Jacquard looms by 1843, then Hattersley and in time followed by Northrop and Sulzer looms in the 1960s, to facilitate ever increasing demand for competitively priced larger orders and finer cloths.

As Quakers and pioneers of social progress, many benefits were set in place for the welfare of the employees with company owned housing, a nursery, one of the first industrial nurseries in the country, a canteen, chapels, schools and sports facilities for rugby, football and swimming. There were annual sporting matches, outings and parties at Christmas, and camps in the summer.

In 1873 a scheme was initiated to offer profit sharing, free medical attendance, compulsory insurance against sickness and company pensions. This preceded measures put in place by Lloyd George by forty years. Later generations of employees were encouraged to join the textile unions and company delegates were appointed who joined the monthly board meetings.

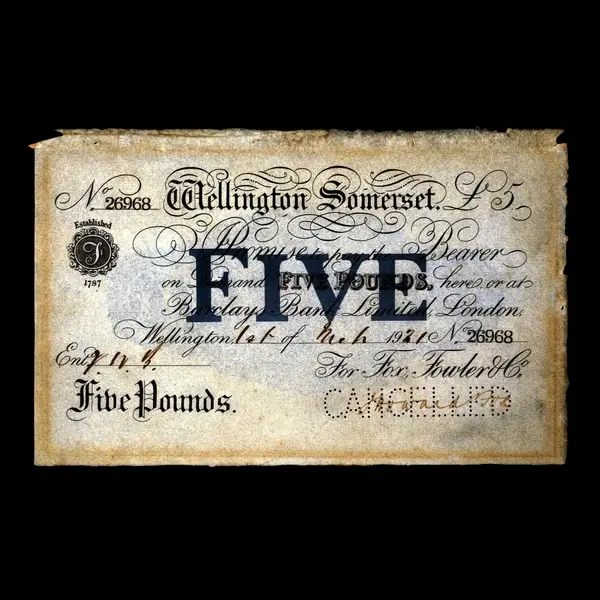

Thomas Fox set up his own bank in 1787, which later became Fox Fowler & Co., initially to facilitate paying suppliers and receiving customers’ payments, and to guarantee wages and savings, and run alongside the woollen business. This was the last British privately owned bank to issue their own bank notes until February 1921, when Howard Fox, after some years of discussion with his uncle, Howard Lloyd, general manager of Lloyds Bank, 1871–1902, sold the 55 branch bank to Mr R. Vassar-Smith at Lloyds Bank.

The company employed about 5,000 people in the height of its output, in Wellington and at their subsidiary factories at Cullompton, Culmstock, Uffculme, Wiveliscombe, Weston super Mare and the William Bliss mill at Chipping Norton acquired in 1900. By 1919 Fox Brothers’ turnover peaked at £1.5M. Many generations of the same family and many employees spending their entire working lives with Fox Brothers. Young employees were trained as apprentices, whilst a large maintenance department ensured the smooth operation of the machinery.

The Industrial Revolution heralded the coming of the Grand Western Canal to Wellington in 1835, followed by the Bristol and Exeter Railway in 1843 with a private siding for the mill. An invoice from, ‘Southan, Evans, and Co., Railway and General Carriers both by Land and Water throughout’, dated 1843, details goods dispatched to Fox Brothers totalling £10 7s 1d.

Fox Brothers, who had produced scarlet serge for the British Army, prior to 1884 were instrumental in 1900 in introducing khaki dye. It is alleged the colour was approved by the Prince of Wales and the War Office. During the First World War, 8,000 miles of khaki cloth were produced for clothing alongside 70,000 pairs of Puttees per week, and production of Puttees both straight and spiral, was to continue until the early 1980s when they were still worn by a number of colonial forces.

Transport and communication progressed and in 1963 the company bought their first lorry to deliver cloth on a weekly basis to London, the Midlands and Yorkshire. This was free delivery. By the 1970s the advent of the telex ensured orders could be placed and dispatched at short notice.

Fox Brothers continues its 250 years’ tradition as a unique and iconic British textile manufacturer supplying outstanding natural wool fabrics of the highest quality to a discerning worldwide customer base.

Laetitia Grant (Fox) & Simon Fox

Fox Brothers was one of the earliest entrants into the wool industry in the UK, having its roots as a cottage industry in 1745. The company was officially founded by Thomas Fox in Wellington 1772. During the Industrial Revolution the company brought wool sorting, spinning, drying and weaving under one roof. It once owned nine mills and employed nearly 5,000 workers. During the First World War it won a War Office contract to provide 852 miles (1,371 km) of khaki coloured cloth for military puttees.

Fox Brothers makes wool, worsted, cashmere and was the original creator of flannel for use in suit making and held the Trademark for ‘Flannel’ up to the 1950s. The company uses looms which are 50 years old and maintains a pattern archive dating back to its foundation, said to be ‘one of the most significant textile (company) archives in the British Isles’. Fox Brothers has made cloth for the suits of several famous people including flannel for Bob Hope, chalk stripe for Winston Churchill and PoW check for the Duke of Windsor. Hollywood legend Cary Grant was often photographed wearing Fox Flannel, at a time when leading men were expected to provide their own wardrobe for the films in which they starred.

Fox Brothers has won two Queen’s Awards. The first was won in 1966, the year the award scheme was founded, for their export sales. The second was in 2006 in recognition of them manufacturing the world’s lightest weight wool and cashmere flannel. The company released new versions of one of their 1782 pattern flannels for the Autumn/Winter 2007 season, using all British wool.